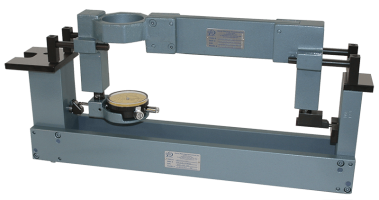

LDF series production gages utilize fixed frames which are more rigid, lighter and more compact than LDA series adjustable gages. LDF gages are normally used for tight tolerances and built to order based on application requirements

LDF Series Large Diameter Gages Features:

- Available with ISO 17025 certification.

- Standard gaging depth range is 0-1". Optional gaging depth of 2" - 5" is available.

- Standard gaging contact travel is .100".

- Standard LDF frame clearance is .75".

- Standard with part #2DM125-05 .0005" graduation dial indicator.

- Three point hardened steel rests.

- Indicator and housing rotate 360 degrees for best viewing angle.

- LDF series requires a part print.

- Rigid steel tubing with thermal isolation grips, reduces thermal expansion, tube weighs only 1.165 lbs/ft

- Available in carbon fiber

| Title Sort descending | Gaging Travel | Contact Type | Frame Clearance | Gaging Depth | Range | |

|---|---|---|---|---|---|---|

| |

LDF-12 | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 6 to 12", 150 to 300mm |

| |

LDF-12 Carbon Fiber | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 6 to 12", 150 to 300mm |

| |

LDF-18 | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 12 to 18", 301 to 460mm |

| |

LDF-18 Carbon Fiber | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 12 to 18", 301 to 460mm |

| |

LDF-24 | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 18 to 24", 461 to 610mm |

| |

LDF-24 Carbon Fiber | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 18 to 24", 461 to 610mm |

| |

LDF-30 | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 24 to 30", 611 to 760mm |

| |

LDF-30 Carbon Fiber | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 24 to 30", 611 to 760mm |

| |

LDF-36 | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 30 to 36", 761 to 915mm |

| |

LDF-36 Carbon Fiber | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 30 to 36", 761 to 915mm |

| |

LDF-42 | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 36 to 42", 916 to 1070mm |

| |

LDF-42 Carbon Fiber | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 36 to 42", 916 to 1070mm |

| |

LDF-48 | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 42 to 48", 1071 to 1220mm |

| |

LDF-48 Carbon Fiber | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 42 to 48", 1071 to 1220mm |

| |

LDF-54 | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 48 to 54", 1221 to 1370mm |

| |

LDF-54 Carbon Fiber | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 48 to 54", 1221 to 1370mm |

| |

LDF-60 | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 54 to 60", 1371 to 1525mm |

| |

LDF-60 Carbon Fiber | .100" | Choice of Steel Pin, Carbide Ball, Steel Shovel, Carbide Shovel and Extended Carbide Shovel | .75" | 0-1" | 54 to 60", 1371 to 1525mm |

| Attachment | Size |

|---|---|

| ldf series.pdf | 688.57 KB |

This design can be used on the LDF, LDDF, or the LDLTF to increase the rigidity of the vertical gaging shafts by extending the support castings up to 5.5" deeper. It is generally recommended to use this type of frame design if the gaging depth exceeds 6". Add "-HF" to the part # of the basic gage to select this option.

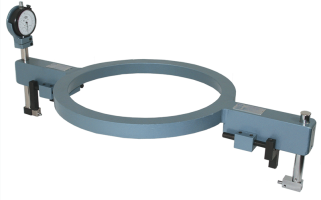

This design can be used on LDF, LDDF, or LDLTF. The Donut Frame design permits the gage to completely encircle a large obstruction such as the part’s hub, case, clamp, or fixture setup. Special size Donut Frames are also available.

Due to part configuration, it is sometimes necessary for the gage frame to rest internally or externally to the check dimension. Holding fixtures used during the machining operations can introduce further restrictions that may require gages to rest on fixture pads located outside or inside the part.

This design permits the gage frame to bridge over short center obstructions such as posts, clamps, or raised contours. These castings extend and support the gaging extension shafts in order to gain measuring rigidity. This raises the frame 2.75". Add "-BF" to the part # of the basic gage for this option.

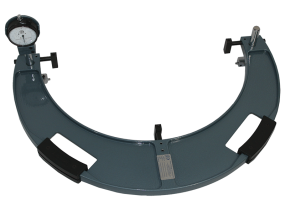

LDC series "C" frame gages are used for applications where the gage cannot be placed directly over the part. The frame is intended to partially encircle the part and is "side loaded" during use. Cam style (LDF), lever style (LDLT), or direct read type (LDD) transfer mechanisms can be used on this frame.