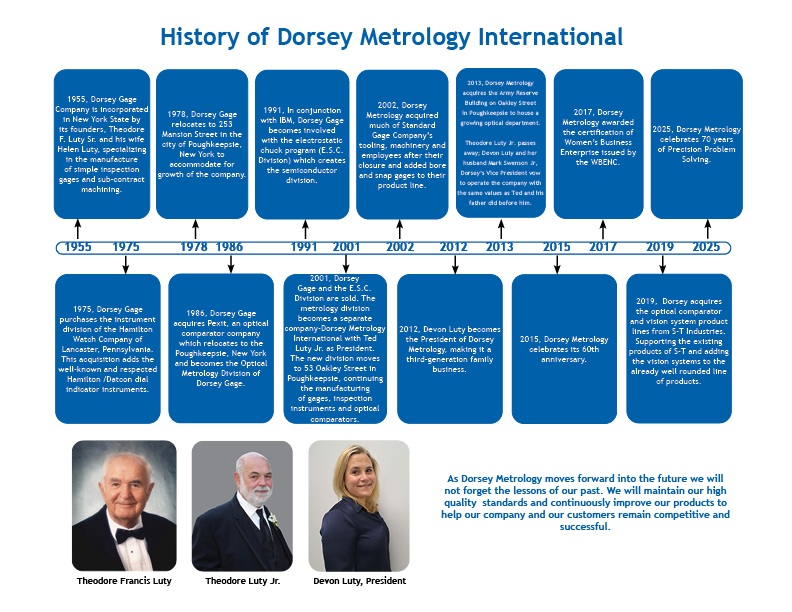

What started as a machine shop specializing in the manufacture of simple inspection gages and subcontract machining, “The Dorsey Gage Company,” founded in 1955, now continues in its third generation as Dorsey Metrology International. Designated as a Women-Owned Business by WBENC, Dorsey prides itself on our outstanding customer relations including the highest quality products, service and support.

With an impressive selection of hand-held and bench top dimensional measurement instruments, Dorsey addresses a wide range of measurement applications, many with alternative approaches to achieve the same purpose, as well as unique items not available elsewhere. In addition to the Dorsey / Standard dial bore gages and snap gages that are the benchmark for gage inspection in America, all our products are designed with superior features. All these instruments can be used with the Dorsey family of “High Amplification” and “Traditional” dial indicators or digital indicating devices.

Dorsey has built its reputation as a leader in the field of large component dimensional measurement. Our expertise brings together the largest selection of measurement movements, frame configurations, sizes, materials, contact points, rests and accessories, all with the knowledge of how to apply them to any large part inspection requirement.

In the optical field, Dorsey is one of the few remaining domestically manufactured optical comparator product lines. Our optical comparators are manufactured on the foundation of rigidity and accuracy, and we have tightened manufacturing tolerances to maintain uncompensated absolute inherent accuracy.

As further commitment to the quality of our products and services to our customers, Dorsey Metrology Calibration Laboratory is accredited by A2LA to ISO 17025 General Requirements for Competence of Testing and Calibration. This accreditation has allowed Dorsey to remain highly competitive in the ever-changing manufacturing sector and encourages even further confidence in the excellence of our products.

Over our 70-year history, Dorsey has endeavored to improve and develop our products continuously. We have achieved success by modernizing and streamlining industry standards to make more robust products; including adding carbon fiber to our lineup. As an organization, we value our reputation as a problem solver and are ready to be of service by suggesting gages for any application, standard or special.