Description

The Benchmark 14H is an Erect Image benchtop comparator and is another example of our expanding range of products. This new comparator has the same high quality features as the current product line, with an erect projection image and our "ultra-precision" crossed roller bearing stage system, but in a smaller package. The measurement scales have zero backlash and are mounted in the center of the stage travel which provides maximum measurement accuracy. The optional extra long-life LED surface illumination is another Dorsey innovation.

Feature List

- Erect and reversed profile image

- 14" (350mm) vertical screen for optimum viewing, high resolution ground glass screen with 90 degree cross lines, with calibration reticle and chart clips

- Machined chart ring with vernier protractor, 1 minute graduation facilitates optimal alignment

- Coated telecentric parfocal optics

- Quick change single lens mount

- Integrated hood

- Solid cast iron, nickel plated stage

- X&Y solid rail crossed roller bearings

- Single universal dovetail stage

- 16" x 4" (400x100mm) overall stage size

- 8" / (200mm) X-axis travel with quick release

- 4" / (100mm) Y-axis travel (vertical movement/rise and fall)

- 50 lbs capacity

- ± 5 degree light source helix adjustment

- LED surface illumination

- 1/4 micron scales are standard equipment

- NIST traceable calibration certificate

- 2 year limited warranty

Optional Features

- Internal edge detection

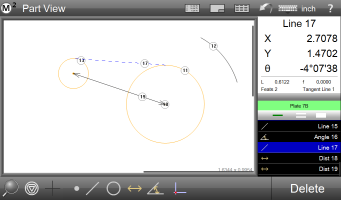

- Choice of readout options

- Output for electronic rotary screen protractor (Q-axis) on readout with selectable 1 minute or 1/100 of a degree resolution

- Harsh Environment package

- Additional lens magnifications available

- Tooling

Profile Illumination

Built-in 24V/150W direct collimated halogen

Surface Illumination

2-Triple LED lights

Screen Size

14” (350mm) Ground glass with cross-lines

Stage Specs

Cast iron, nickel plated, 16” x 4” single dovetail

8” (200mm)

4” (100mm)

Stage Focus

1.5" (38mm)

Stage Accuracy

Within +/- 0.004mm +[(L/20).001]

0.00025mm/.000010”

Repeatability of Scales

+/- 1 Scale count (0.00025mm/.000010”)

Lens Magnification

10x, 20x, 50x, 100x

Profile Accuracy

+/- .10%

Surface Accuracy

+/- .15%

Power Requirements

120V or 240V AC, 50/60 Hz, 10 Amp

Weight

250 lbs/113 kg

Warranty

2 years

NIST Cert

Yes

| Attachment | Size |

|---|---|

| 14H Press Release | 422.12 KB |

| Accessories & Calibration Tooling | 658.34 KB |

| Digital Readouts & Software | 823.87 KB |

| How to Select the Right Comparator | 583.37 KB |

| Model 14H Horizontal Beam | 482.33 KB |

| Work Stage Tooling | 1.58 MB |

Part Number

Lens Magnification

10X

Max Part Diameter

162mm

Focal Distance

81mm

Lens Face Diameter

54mm

Part Number

Lens Magnification

20X

Max Part Diameter

162mm

Focal Distance

81mm

Lens Face Diameter

47mm

Part Number

Lens Magnification

50X

Max Part Diameter

102mm

Focal Distance

51mm

Lens Face Diameter

28mm

Part Number

Lens Magnification

100X

Max Part Diameter

86mm

Focal Distance

43mm

Lens Face Diameter

27mm

Heavy Duty Locking Metal Stand

Part Number

ACC-CAB27

Feature List

- 28.5" x 22.3" x 27" dimensions

- Laminate top

- 2 Heavy duty locking drawers 5" & 11" deep

- Up to 1000 lbs. capacity

Part Number

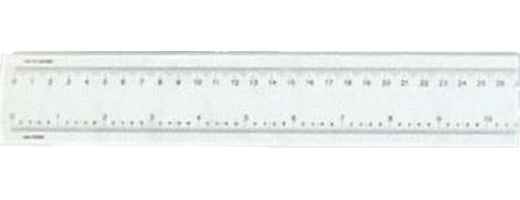

ACC-MAGMM

Feature List

- 3" X 16" Overall size

- 14" scale

- Fitted storage box

- NIST Traceable accuracy certification

- For magnification calibration (measuring the projected image)

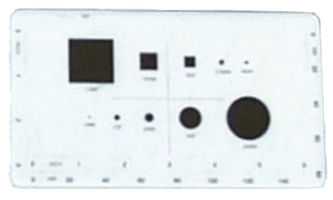

Part Number

ACC-MAGPM

Feature List

- Chrome targets with 6" x 3" rule

- Inch/metric graduations

- Fitted storage box

- NIST Traceable accuracy certification

- For linear calibration and projection of magnification image

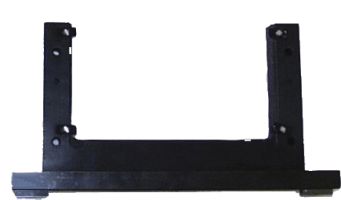

Part Number

ACC-MAGPMF

Feature List

- Designed to accurately hold and protect ACC-MAGPM during use on horizontal optical comparators

- Precision ground base

- Wooden storage box

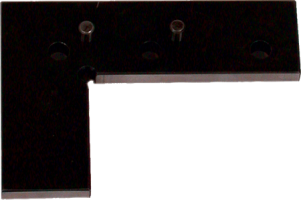

Fixture Banking Plates 6" x 1"

Part Number

ACC-BF

Feature List

- Precision ground steel

- Reversible for left or right bank

- Can be used on horizontal stages

- Part# ACC-BF 6" x 1" (150x25mm)

Fixture Banking plates 3" x 2.5"

Part Number

ACC-LBF

Feature List

- Precision ground steel

- Reversible for left or right bank

- Can be used on horizontal stages

- Part# ACC-LBF 3" x 2.5" (75x63mm)

Part Number

ACC-VB1

Feature List

- 90 degree V 2.7" (70mm)high

- Hardened and ground steel

- Precision V block

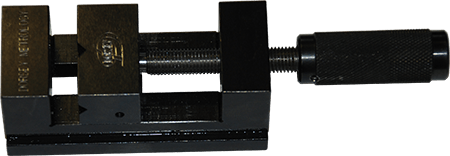

Part Number

ACC-V1

Feature List

- Jaw opening of 1.25" (32mm)

- Precision ground steel

- Vertical and horizontal V

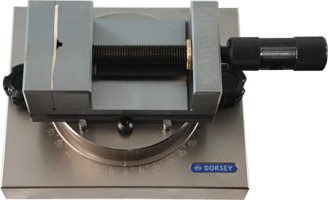

Part Number

ACC-V2

Feature List

- Jaw opening of 2.12" (54mm)

- Precision ground steel

- Vertical and horizontal V

Part Number

ACC-VF7x5

Feature List

- Used to mount flat parts on horizontal comparators

- 7" x 5" (178x127mm) glass

- 2 Chart clips & V

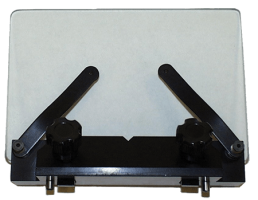

Part Number

ACC-PVS

Feature List

- For use with ACC-V1 vise only.

- Fixture to hold vise in 2 axes (ACC-V1 sold separately)

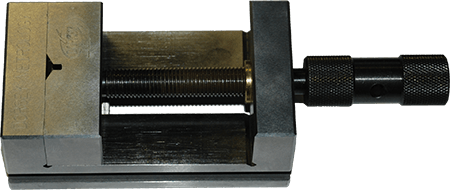

Part Number

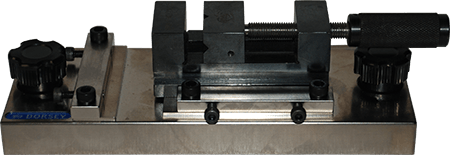

ACC-RV1

Feature List

- Jaw opening of 1.25" (32mm)

- Precision ground steel

- Positions vise in X, Y, or Z axis

- 360 degree rotation with 1 degree graduation

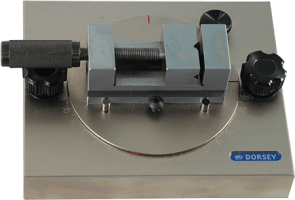

Part Number

ACC-RV2

Feature List

- Jaw opening of 2.12" (54mm)

- Precision ground steel

- Positions vise in X, Y, or Z axis

- 360 degree rotation with 1 degree graduation

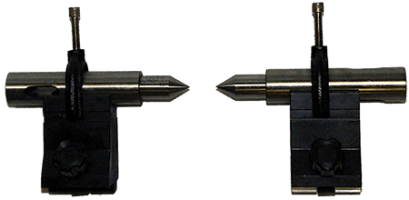

Part Number

ACC-VBC5.38

Feature List

- Matched ground hardened steel

- 90 degree V

- 5.385" (137mm) tall

- 3/4" (19mm) diameter centers with fine adjustment

- 1.25" (32mm) fixed center

Heavy Duty V Block & Center Kit

Part Number

ACC-VBCHD

Feature List

- Matched ground cast iron

- 90 degree V

- 5" (127mm) tall

- 1" (25mm) diameter centers with interchangeable Morse taper insert and clamps

Part Number

ACC-FBX

Feature List

- Used to make custom fixtures

- Precision machined steel

- 2" (50mm) Part #ACC-FB2

- 4" (100mm) Part #ACC-FB4

- 6" (150mm) Part #ACC-FB6

- 8" (200mm) Part #ACC-FB8

Precision V Block & Center Kit

Part Number

ACC-VBC2.5

Feature List

- Matched ground hardened steel

- 90 degree V

- 2.7" (70mm) tall

- 1" (25mm) diameter centers with interchangeable Morse taper insert and clamps

Part Number

ACC-CAB32

Feature List

- 24" x 36" x 32" dimensions

- Welded tubular steel

- Up to 350 lbs capacity

- Powder coated finish

- Solid Maple wood top