Dial bore gages are used to quickly inspect hole diameter as well as to detect and measure all kinds of bore conditions such as taper, bell-mouth and out-of roundness. They in no way depend upon a sense of "feel" as is the case with non-indicating types. Machine operators find our bore gages to be particularly useful in making quick, accurate adjustments to bring work-pieces within tolerance. In this application, the reading on the dial tells the exact amount of tool correction needed and eliminates uncertain, "creep-up" methods of making adjustments.

The reliable accuracy for which these standard bore gages are known is due to a delicately responsive gaging plunger and a positive centralizing mechanism that correctly positions the gage in the bore. After setting to a master, diametral measurements are obtained by rocking the gage in the bore and noting the greatest deflection of the dial hand.

The regular type dial bore gage is intended for the usual situation where there is ample space in front of the bore opening. For gaging in restricted spaces, or to facilitate reading where other limitations are imposed, additional standard bore gage styles are available. If your application require additional range extension, please contact us for quotation.

Standard Style Bore Gage Features

- Available with ISO 17025 certification.

- Comfortable & ergonomic well balanced handle, can be removed to gain clearance in restricted areas.

- Optional shock proof dial indicator with .001", .0005", .0001", or .00005" (.001mm, .002mm, .01mm) resolution available in single or multi revolution models. Available with Dorsey's digital housings for use with most digital indicator models.

- Precision machined aluminum dial unit housing.

- Precisely machined cast phosphor bronze gaging head for sensitivity and durability.

- Stainless steel bore gage extension tubing in a wide variety of standard and special lengths.

- Carbon fiber or stainles steel extra length extension tubing up to 144".

- Thermally insulated high impact resistant shield protects extension tubing.

- Unique "tandem" centralizer uses matched and lapped components to ensure accurate and repeatable centralization.

- Replacable contacts available in steel, carbide or diamond.

- Proven bell crank transfer is accurate and linear over its entire range.

- Precisely machined cast phosphor bronze gaging head for sensitivity and durability.

- All bore gage sizes utilize the same dial unit housing for extreme versality.

Additional bore gage styles designed especially for applications where space restrictions or gaging positions are not suitable to use of standard style bore gages housing.

| Title Sort descending | Graduation | Gaging Travel | Range | |

|---|---|---|---|---|

| |

DS-B1-10102 Bore Gage | .00005" | .025" | 1.00 - 1.53", 25.4 - 38.9mm |

| |

DS-B1-10103 Bore Gage | .00005" | .025" | 1.50 - 2.16", 38.1 - 54.8mm |

| |

DS-B1-10104 Bore Gage | .00005" | .025" | 2.12 - 3.13", 54.0 - 79.5mm |

| |

DS-B1-10105 Bore Gage | .00005" | .025" | 3.09 - 6.13", 78.5- 156mm |

| |

DS-B1-10106 Bore Gage | .00005" | .030" | 6.00 - 12.13", 152.5 - 308.0mm |

| DS-B1-10107 Bore Gage | .00005" | .030" | 10.00 - 24.00", 254 - 610mm | |

|

DS-B1-10108 Bore Gage | .00005" | .030" | 21.00 - 36.00", 533 - 915mm |

| |

DS-B1-10112 Bore Gage | .00025" | .025" | 1.00 - 1.53", 25.4 - 38.9mm |

| |

DS-B1-10113 Bore Gage | .00025" | .025" | 1.50 - 2.16", 38.1 - 54.8mm |

| |

DS-B1-10114 Bore Gage | .00025" | .025" | 2.12 - 3.13", 54.0 - 79.5mm |

| |

DS-B1-10115 Bore Gage | .00025" | .025" | 3.09 - 6.13", 78.5- 156mm |

| |

DS-B1-10116 Bore Gage | .00025" | .030" | 6.00 - 12.13", 152.5 - 308.0mm |

| DS-B1-10117 Bore Gage | .00025" | .030" | 10.00 - 24.00", 254 - 610mm | |

|

DS-B1-10118 Bore Gage | .00025" | .030" | 21.00 - 36.00", 533 - 915mm |

| DS-B1-10122 Bore Gage | 0.001mm | .025" | 1.00 - 1.53", 25.4 - 38.9mm | |

| DS-B1-10123 Bore Gage | 0.001mm | .025" | 1.50 - 2.16", 38.1 - 54.8mm | |

| DS-B1-10124 Bore Gage | 0.001mm | .025" | 2.12 - 3.13", 54.0 - 79.5mm | |

| |

DS-B1-10125 Bore Gage | 0.001mm | .025" | 3.09 - 6.13", 78.5- 156mm |

| DS-B1-10126 Bore Gage | 0.001mm | .030" | 6.00 - 12.13", 152.5 - 308.0mm | |

| DS-B1-10127 Bore Gage | 0.001mm | .030" | 10.00 - 24.00", 254 - 610mm | |

|

DS-B1-10128 Bore Gage | 0.001mm | .030" | 21.00 - 36.00", 533 - 915mm |

| |

DS-B1-11102 Bore Gage | .0001" | .025" | 1.00 - 1.53", 25.4 - 38.9mm |

| |

DS-B1-11103 Bore Gage | .0001" | .025" | 1.50 - 2.16", 38.1 - 54.8mm |

| |

DS-B1-11104 Bore Gage | .0001" | .025" | 2.12 - 3.13", 54.0 - 79.5mm |

| |

DS-B1-11105 Bore Gage | .0001" | .025" | 3.09 - 6.13", 78.5- 156mm |

| DS-B1-11106 Bore Gage | .0001" | .030" | 6.00 - 12.13", 152.5 - 308.0mm | |

| |

DS-B1-11107 Bore Gage | .0001" | .030" | 10.00 - 24.00", 254 - 610mm |

| DS-B1-11108 Bore Gage | .0001" | .030" | 21.00 - 36.00", 533 - 915mm | |

| |

DS-B1-12102 Bore Gage | .0001" | .025" | 1.00 - 1.53", 25.4 - 38.9mm |

| DS-B1-12102M Bore Gage | .0001", .002mm | .025" | 1.00 - 1.53", 25.4 - 38.9mm | |

| DS-B1-12103 Bore Gage | .0001" | .025" | 1.50 - 2.16", 38.1 - 54.8mm | |

| DS-B1-12103M Bore Gage | .0001", .002mm | .025" | 1.50 - 2.16", 38.1 - 54.8mm | |

| |

DS-B1-12104 Bore Gage | .0001" | .025" | 2.12 - 3.13", 54.0 - 79.5mm |

| DS-B1-12104M Bore Gage | .0001", .002mm | .025" | 2.12 - 3.13", 54.0 - 79.5mm | |

| DS-B1-12105 Bore Gage | .0001" | .025" | 3.09 - 6.13", 78.5- 156mm | |

| DS-B1-12105M Bore Gage | .0001", .002mm | .025" | 3.09 - 6.13", 78.5- 156mm | |

| |

DS-B1-12106 Bore Gage | .0001" | .030" | 6.00 - 12.13", 152.5 - 308.0mm |

| DS-B1-12106M Bore Gage | .0001", .002mm | .030" | 6.00 - 12.13", 152.5 - 308.0mm | |

| |

DS-B1-12107 Bore Gage | .0001" | .030" | 10.00 - 24.00", 254 - 610mm |

| DS-B1-12107M Bore Gage | .0001", .002mm | .030" | 10.00 - 24.00", 254 - 610mm | |

|

DS-B1-12108 Bore Gage | .0001" | .030" | 21.00 - 36.00", 533 - 915mm |

| DS-B1-12108M Bore Gage | .0001", .002mm | .030" | 21.00 - 36.00", 533 - 915mm | |

| |

DS-B1-13102 Bore Gage | .0005" | .025" | 1.00 - 1.53", 25.4 - 38.9mm |

| |

DS-B1-13103 Bore Gage | .0005" | .025" | 1.50 - 2.16", 38.1 - 54.8mm |

| |

DS-B1-13104 Bore Gage | .0005" | .025" | 2.12 - 3.13", 54.0 - 79.5mm |

| Attachment | Size |

|---|---|

| Instructions for Standard Bore Gage | 566.53 KB |

| DBG-2 | 78.93 KB |

| DBG-3 | 79.09 KB |

| DBG-4 | 58.81 KB |

| DBG-5 | 102.1 KB |

| DBG-6 | 136.15 KB |

| Bore Gaging Overview | 477.4 KB |

| Standard Bore Gage Features | 565.63 KB |

| Standard Bore Gage Models | 419.82 KB |

| Standard Bore Gage Options | 650.43 KB |

| Standard Bore Gage Specs | 189.04 KB |

| Standard Bore Gage Style 1 | 1.37 MB |

| Standard Bore Gage Styles | 836.11 KB |

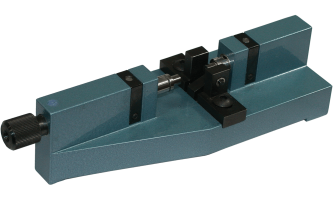

For vertical axis bores at eye level; best choice for bench inspection applications.

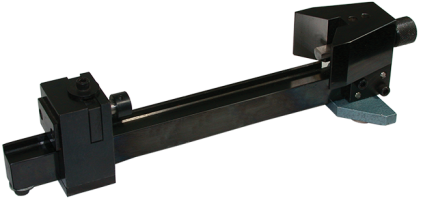

For vertical axis bores below eye level.

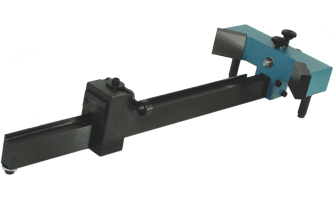

For limited access applications.

For limited access applications.

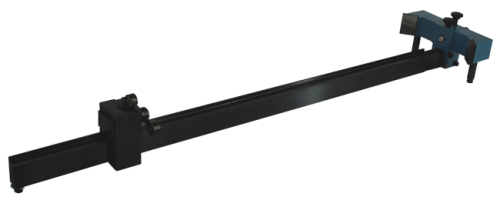

For jig boring or jig grinding machine operations; designed to avoid disturbing the machine tool setup. Also for restricted areas or applications that might be hazardous to the operators' hand.

DBM-250 Adjustable Bore Gage Setmaster

DBM-1000 Adjustable Bore Gage Setmaster

DBM-6000 Adjustable Bore Gage Setmaster

DBM-12000 Adjustable Bore Gage Setmaster

DBM-24000 Adjustable Bore Gage Setmaster