As manufacturers strive for six sigma manufacturing processes, and zero defects, the role of the quality department has significantly changed. Quality departments must now become actively involved in the manufacturing process from engineering to product packing and shipment.

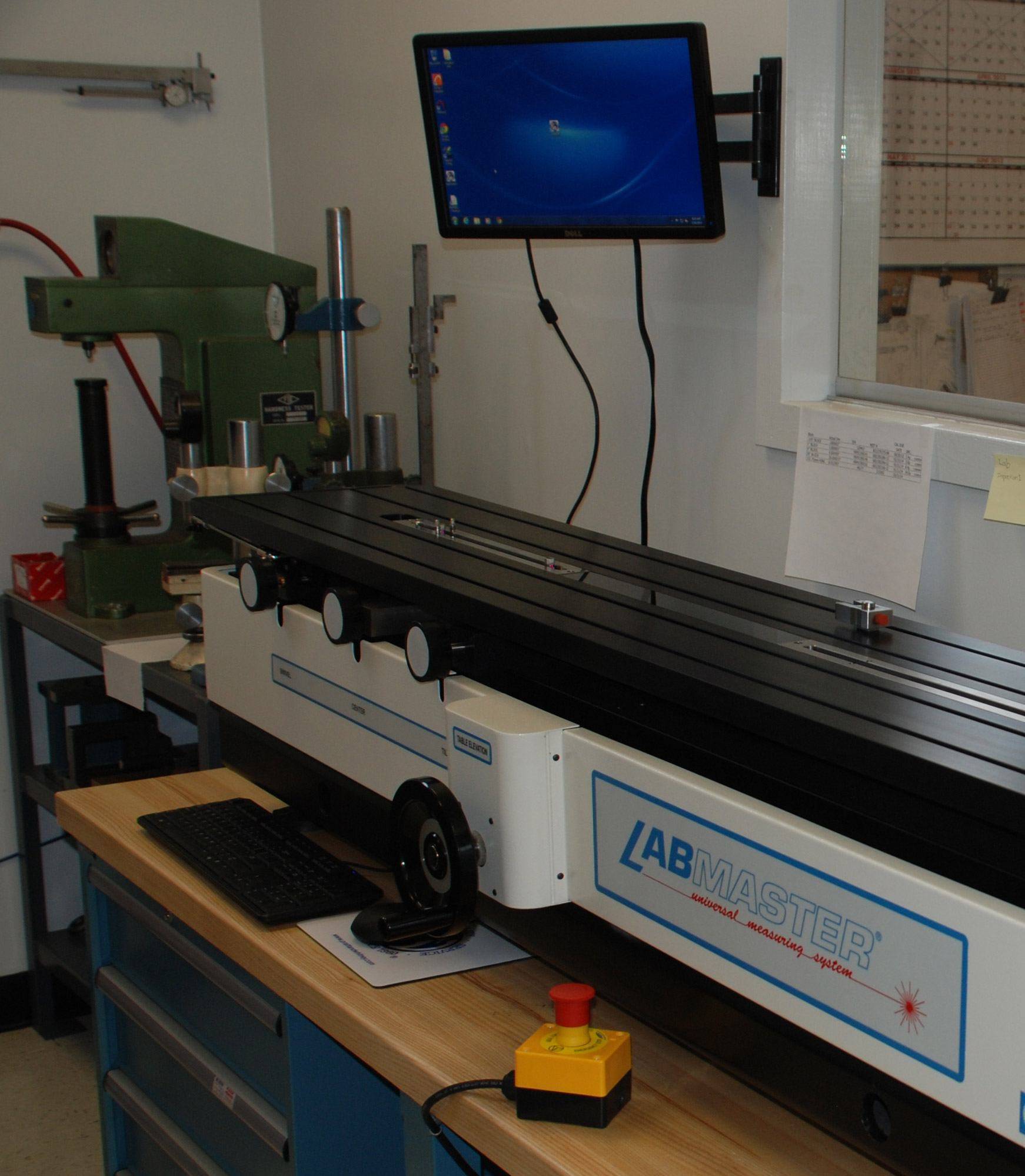

Optical non-contact and hybrid optical/contact inspection systems will provide the tools necessary for quality managers to accomplish this formidable task. Computerization of these systems allows integration of Statistical Process Control (SPC) software packages directly on the inspection instrument. These computerized instruments are capable of being networked so that documentation control and maintenance are automatic and paperless. These computerized optical inspection instruments can and will be connected via the network to the engineering department’s computer aided design (CAD) system. This enables the quality department to download and import product part prints for automated programming of inspection routines. It will also allow the quality department to export and upload actual inspection results in CAD format for the engineering department to review. In addition, traditional contact style production gages, such as snap gages or bore gages, can be integrated via SPC connections into the inspection package to provide a complete quality solution.

The future of Optical Inspection Instruments

As optical inspection technology matures, is further automated, and coupled with other inspection technologies these fully automated instruments will be completely integrated with the manufacturing line. Complex inspection systems will be able to inspect a manufacturing process on line while the parts are being manufactured. Optical inspection instruments are a non-contact form of measurement that will allow the inspection of a part while the part is actually moving and being machined on the machine tool. Automated communication between the inspection instrument and the machine tool will close the loop and provide the machine tool with the necessary offsets and adjustments required meet the goal of any manufacturing process - to manufacture a virtually perfect part, every time.